Thanks to our know-how we can follow you from planning to realization of both simple and complex details.

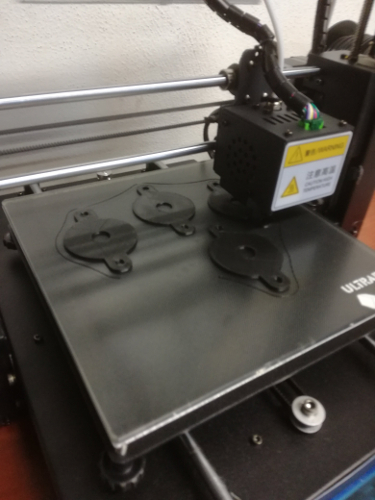

Our structure collaborates with handcrafted companies able to supply both laser-cut sheets and tubes while we can directly produce plastic parts thanks to the use of filament 3D printing.

Once we have analyzed your needs, we develop a REAL sample that can be directly tested. This is an important side of the process : you can directly taste the functionality of the piece in order to understand its advantages and eventually cancel any faults .This allows us to make a careful analysis of the product to INDUSTRIALIZE it.

This leads to countless advantages:

- Real production cost

- Real analysis and evaluation by the commercial offices.

- Preview of the article in SOLID FORMAT.

|

For example Customer inquiry: Type of customer : pet shop store . in need of exposing various dog leashes and pet toys - different sizes and shapes articles Customer expectation : optimization of the exposure of its products ... CO.NU.GR.AN. SOLUTION : - one turnable shelf with a different configuration of the articles ; each article has to be well and clearly shown to the target |

|

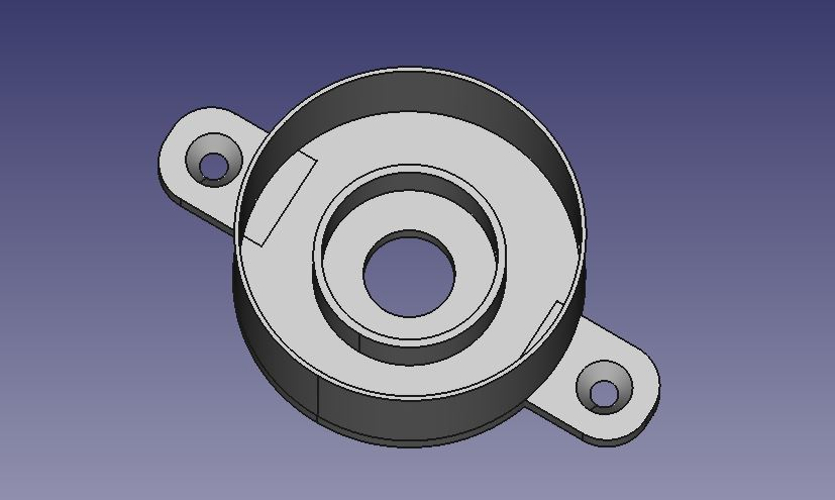

Co.nu.gr.an. starts from the kinematic and mass study |

|

|

Co.nu.gr.an. handcrafts the antifriction bearings |

|

...studied the rotating parts and special holding hooks |

|

|

Co.nu.gr.an. assembled the finished piece and worked on its illumation |

|

the final pieces is ready ... SATISFIED CUSTOMER .... |

|